Testing and Evaluation of Active, Passive & SMD Components

In its endeavour to maintain the highest level of quality control and assurance, extensive screening and testing of a wide range of electronic components are undertaken by Pacific before releasing them for use in PCBs or any other sub-system. The test facility built up over a period of time by Pacific has been fully utilised to undertake parametric testing of active and passive electronic components. These tests conducted in accordance with MIL Standards like MIL-883, MIL-750, JSS50115:2008 etc. for in house purposes are also extended to customers to undertake tests as required by them at a pre – determined tariff.

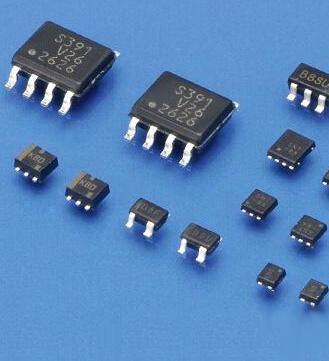

The components tested in this facility include Resistance, Capacitance, Inductance, Diodes, Bipolar Transistors, FETs, UJTs, SCRs, ICs - Linear as well as Digital, Hybrid Devices, Electromechanical, Electromagnetic, Opto electronics, PCB and Laminates etc.

Screening and Qualification of Components

On lines similar to parametric testing, Pacific also offers screening, qualification and testing services in accordance with MIL Standards. The required software and hardware to test microcircuits, discrete semiconductors and passive electronic components are developed in-house. Electrical testing, environmental exposures and Burn-in of electronic components are undertaken to eliminate failures due ‘Infant Mortality’ and to increase reliability of each component. This ensures that all the tested components will meet the demanding requirements of military, aerospace and marine applications.

In addition, Pacific also undertakes after-market screening and re-testing of new ‘old stock’ parts required to be revalidated to laid down specifications. Moreover, on an ‘as required basis’, we undertake development of screening schedules to meet our customer’s requirements.

Dynamic Burn-in of active and passive components

The purpose of a burn-in test is to identify faulty components in the Active and Passive electronic components. Possible initial failures are identified by application of specific temperature and voltage loads thereby increasing assured life of components.

Following tests are conducted by Pacific :

- Diode High Temperature Reverse Biasing (80 to 800VDC)

- Diode Burn-in System

- IC Burn-in System (Digital Integrated Circuits)

- Transistor High Temperature Reverse Biasing (200VDC)

- Transistor Burn-in System